BigRep STUDIO

- Overview

- Features

- Technical Details

- Application

- Material

- Download

FAST AND PRECISE LARGE-SCALE 3D PRINTING

IS FINALLY ACCESSIBLE IN ONE COMPACT PACKAGE

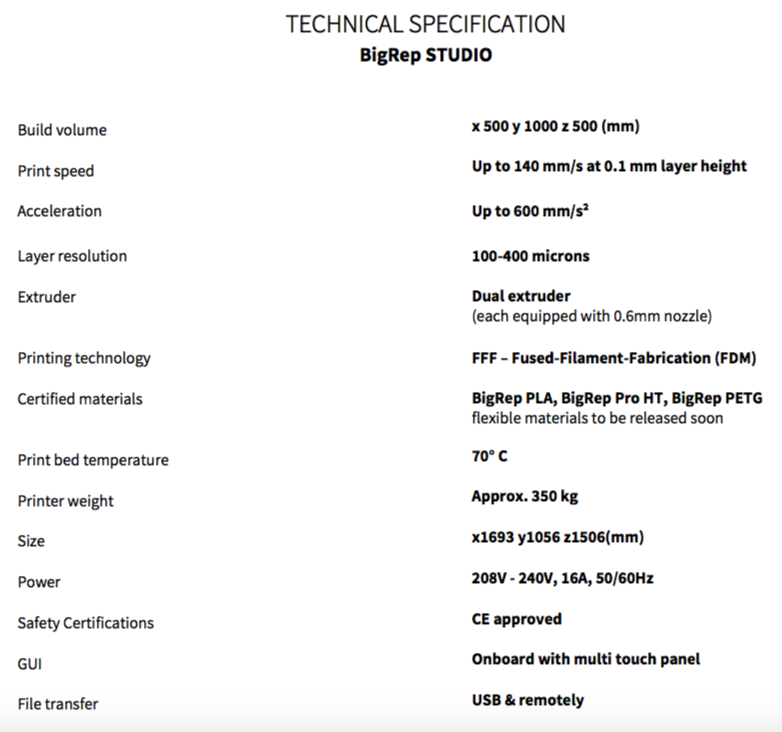

With the BigRep STUDIO, we introduce a workhorse printer that brings a new dimension to large-scale 3D printing.

The print volume of 500 mm x 1000 mm x 500 mm enables continuous printing of large objects in a space-saving package. Because it fits easily through doors, the BigRep STUDIO is optimally sized for set-up in any location.

The direct-drive dual-extruder with a 0.6 mm nozzle has been optimized for both speed and precision, capable of printing flexible materials. The all-metal hot-end allows for printing of a larger variety of high temperature filaments.

Shaped by the winner of the German Design Award 2016, the market-leading BigRep ONE printer, our experts have engineered the STUDIO for professionals across industries to easily and quickly bring their innovative designs to life.

Comfortable to Use

The Ergonomic Design

Raised for maximum user comfort, the BigRep STUDIO stands at an ideal height for everyday use. Keeping everything compact and accessible, two filament spools can be held below the printer, alongside additional storage space.

Accelerated Printing with Precision

The Print Head

The direct drive extruder with a 0.6mm nozzle enables printing using flexible materials, with maximum speed and precision. Its innovative print head was specially designed by BigRep to achieve a high level of detail for large-scale print projects, allowing for a layer height of as little as 0.1mm.

Saves on Space

The Slim Build

The BigRep STUDIO is a 3D printer that slots perfectly into all workspaces. Simpler to transport than other larger 3D printer models, its slender frame easily fits through standard doors in offices and studios, either as one piece or in two parts.

Easy and Intuitive

The Graphical User Interface

A new intuitive user interface on a touch panel PC enables many innovative features such as progress checks, including a webcam upgrade, and a resume print function a er power failure. It includes an option to calibrate print levels while a job is in progress.

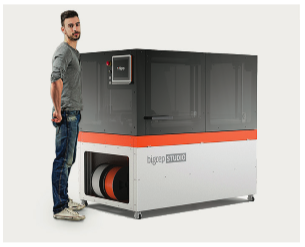

Fast-heating Print Bed

The Print Bed

Prep time is significantly reduced for all print projects, with the STUDIO print bed reaching an optimal adhesion temperature of 60 °C in just 10 minutes. Distance from the print bed can be continually calibrated, allowing for maximum flexibility and control over print levels.

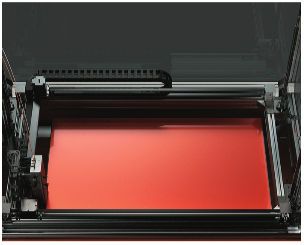

Enclosed Environment

The Glass Slide Walls

The STUDIO has side walls for increased safety, in addition to auto-pause of print jobs upon opening. The sleek glass doors slide back for easy access to the print bed and enable users to visually monitor the printing process

ENGINEERING AND RAPID PROTOTYPING

Faster and more cost-efficient production of prototypes broadens development and design potential for industrial applications. The BigRep STUDIO allows for simple, quick and low-cost manufacturing of product iterations, meaning higher quality products and shorter development times.

RESEARCH AND DEVELOPMENT

The BigRep STUDIO offers new learning, research and innovation possibilities to students, educators and scientists alike. It is a workhorse machine that goes the extra mile, as well as being safe, easy to use and ideal for gaining experience in the production of large-scale objects.

ART, DESIGN AND ARCHITECTURE

The BigRep STUDIO empowers designers, artists and architects to bring previously inconceivable ideas to life. The compact machine can be set up virtually anywhere, meaning creative professionals can now produce objects in their own studios and workshops. Thanks to the STUDIO ́s cost efficient technology, experimenting with new designs can be fast and effortless.