MISSION:SORT- Metal Sorting System

- Overview

- Features

- Technical Details

- Application

- Download

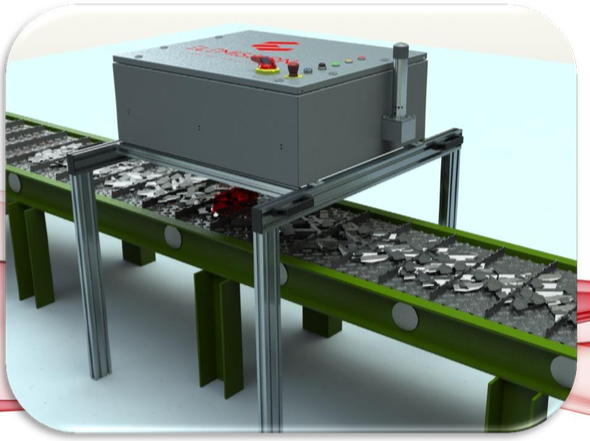

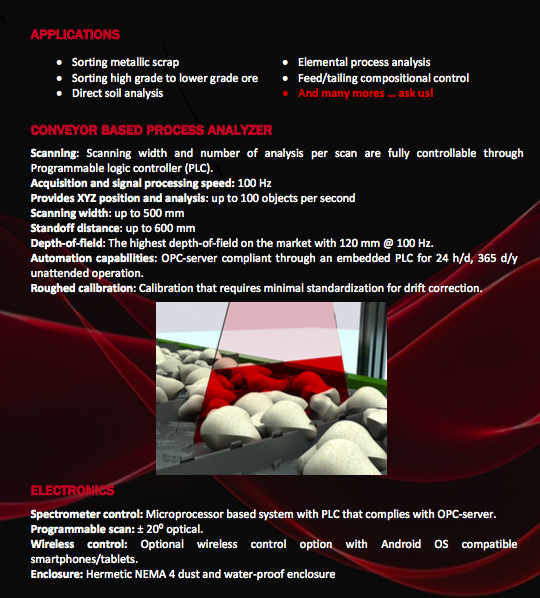

MISSION:SORT has been designed for high throughput sorting as well as roughed process analyzer for recycling or for metallurgical transformation. MISSION:SORT is the first sensor for recycling that reaches more than 100 measurements per second. Moreover, it can resolve small chemical differences within the same alloy base (i.e. aluminum 6111, 6061, etc). In addition, SORT does not emit ionizing electromagnetic radiation such X-Rays and Gamma-Rays

LIBS analysis is, by far, the fastest technology currently on the market to analyze chemical composition in real-time on a conveyor belt. The reasons are many:

-

Versatility: Analysis of any metal or non-conducting material in different shapes and forms

-

Adaptability: can scan a conveyor belt cross-section up to 500 mm

-

Speed: Real time analysis at unmatched pace: 100 objects per second

-

Range: From trace (sub-ppm) to percent concentration levels

-

Accuracy: better than 1% relative or exceed 99% correctly classified

-

Simplicity: No sample preparation, dries and cleans, with an ability to analyse material with

paint, dirt, oxide, water, etc.

-

Savings: Rapid Return on Investment (ROI) and low operating costs

Technical Specifications

-

Scanning speed: 100 Hz

-

Provides position and analysis: 100 Hz

-

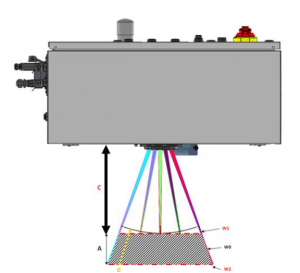

Scanning width: up to 500 mm

-

Standoff distance: up to 600 mm

-

Depth-of-field: 120 mm

-

Acquisition and signal processing speed:

100 Hz

-

Number of analysis per scan: 1 to n

Adjustable trough PLC

-

Automation capabilities: Fully OPC-

server compliant thru an embedded PLC for 24h/d 365 d/y unattended operation.