BigRep ONE

- Overview

- Features

- Technical Details

- Application

- Material

- Download

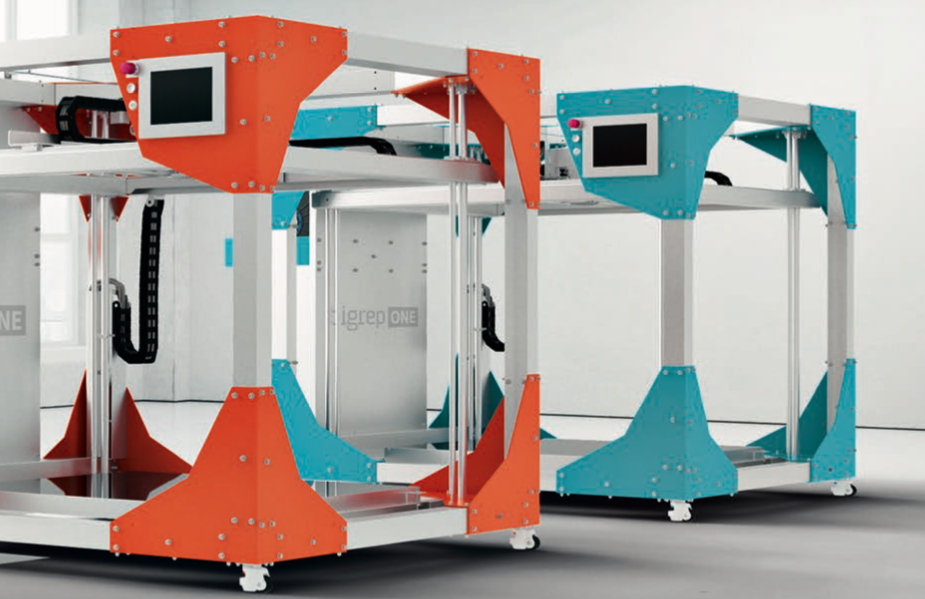

THE MOST ADVANCED LARGE SCALE 3D PRINTING EXPERIENCE

The driving force behind the BigRep ONE hasn’t changed: make large-scale 3D printing affordable and available to more users. To achieve the best possible conditions for printing large objects a lot of new features are being introduced.

The modular print heads have been completely redesigned, in combination with a larger flexible spool holder, this provides the ideal 3D printer for manufacturing large-scale objects. The open format allows the user to have the best view for monitoring the print process. For large scale prints, our new high throughput extruder for 1 and 2mm nozzles allows for the highest throughputs, making the BigRep ONE v3 one of the fastest large-scale 3D printers on the market.

Open and Safe

The Frame Construction

The open format ensures that the user has the best possible view for monitoring the quality and progress of the object at all times. Moving parts have been enclosed for user safety, aided by integrated sensors that ensure precision and user friendliness.

Modular and Independent

The Extruders

The modular print heads operate independently, allowing for unbeatable flexibility when printing in two colors or with a di erent support material (break-away or soluble). They can be easily adjusted and replaced without the need for tools. During the printing process, the inactive print head moves upwards slightly to avoid making contact with the object. The print heads were developed by BigRep’s in-house team and optimized for large-scale printing projects.

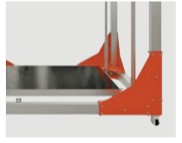

Semi-automatic print bed levelling

The Print Bed

The heated print bed mounted with PI provides optimal adhesion in the printing process right from the outset. Thanks to an integrated automatic inductive sensor, the print bed can be leveled quickly and e ortlessly, reducing prep time considerably.

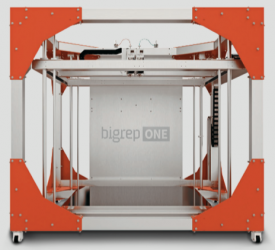

Big, Bigger, the Biggest

The Build Volume

The new BigRep ONE v3 features a build volume of X 1005 mm x Y 1005 mm x Z 1005 mm. With a capacity ofover one cubic meter, the new BigRep ONE v3 provides the largest serially produced FFF 3D printer currently available on the international market.

Spacious and Flexible

The Spool Holder

The spool holder has been designed to fit all standard spool sizes. It can hold several spool of up to 8 kg. A run-outdetection system notifies the user when the pool is about to end. Optionally a filament enclosure box is available toprotect filament from dust and moisture.

Easy and Intuitive

The Graphical User Interface

The new intuitive user interface on touch panel PC enables many new features, such as remote load, check print progress via webcam, resume print a er power failure, and many more.

ENGINEERING AND RAPID PROTOTYPING

Being able to produce prototypes quickly and cost-efficiently opens up new development and design possibilities for industrial users. With the BigRep ONE v3 large numbers of iterations can be simply manufactured without incurring high costs. This means better products and shorter development times.

RESEARCH AND DEVELOPMENT

With the BigRep ONE v3 we provide a tool that news new possibilities for teaching and research to students, teachers and scientists alike. The machine is easy to use, and its open format enables numerous users to observe and experiment with additive manufacturing processes while gaining experience in the production of large-scale objects.

ART, DESIGN AND ARCHITECTURE

The BigRep ONE v3 is a tool that opens up previously inconceivable opportunities to designers, artists and architects. The BigRep ONE v3 can be installed virtually anywhere and put into operation after brief familiarisation. Creative professionals can now produce large objects in their own studios and workshops. Thanks to this cost-efficient technology, trying out various designs quickly and effortlessly is no problem. Even final products of up to one cubic meter in size can be manufactured with the BigRep ONE v3.